Makino high speed machining center

V33i vertical machining center has excellent performance in the maintenance of stability, precision, high rigidity, and shortening the production cycle. Adopting the design of 30,000rpm main shaft, full-axis linear motor, we are able to obtain keep the tolerance of roundness and positioning within 0.003mm and achieve higher accuracy, efficiency, reliability and easier operation. It can meet the special requirements of high-precision clamping fixture, precision multi-cavity rubber and plastic mold and high-precision electrode processing, such as optical, acoustic parts, semiconductor parts, hydrogen fuel cell and other fine processing in mobile phones.

Makino precision CNC EDM machine

The EDGE serial of machines uses Makino's latest IES (Intelligent Expert System) and Super Sparkiv technology, including advanced adaptive power control and adaptive jump control. These adaptive control technologies improve accuracy, reducing cycle time by stabilizing the EDM process.With the help of advanced ultra surface and edge technology, the machining quality and consistent surface finish are improved. Maximum machining speed: 5000 mm/min. Surface roughness: 0.3um Coordinate positioning accuracy: 0.0019mm

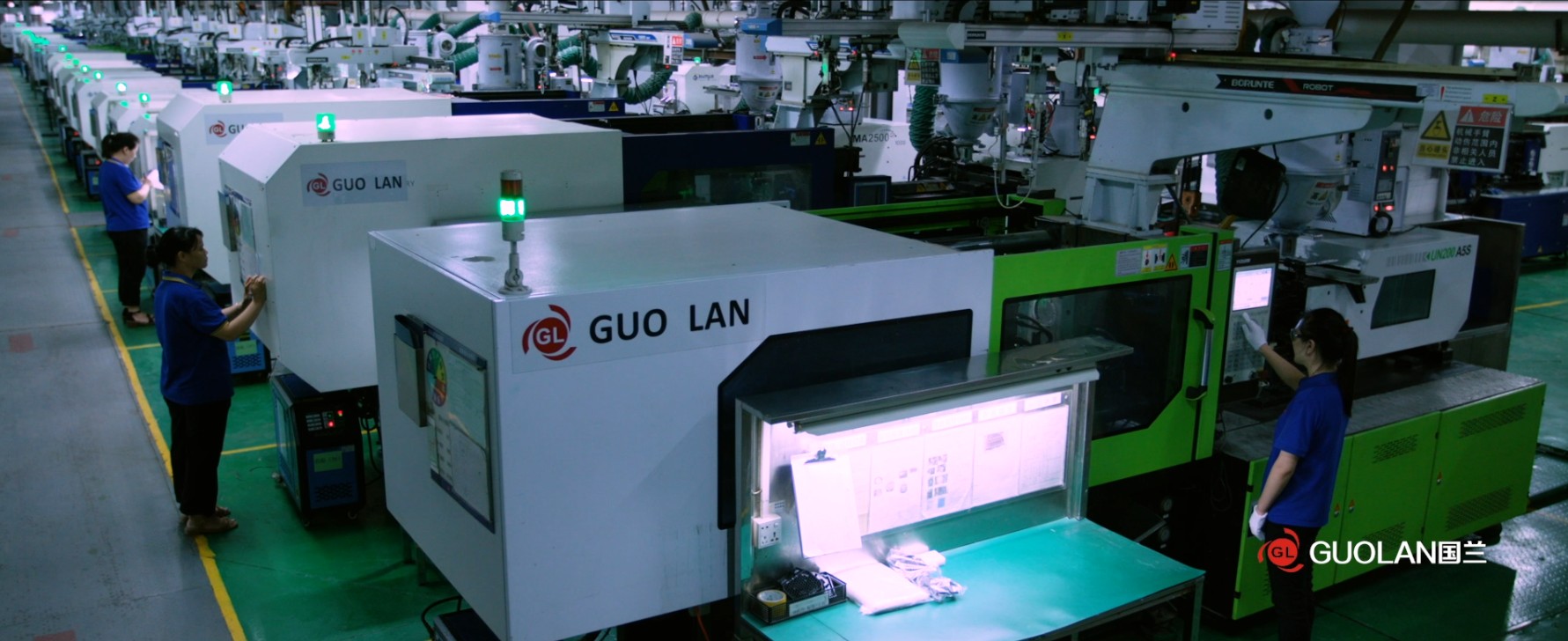

Injection molding equipment

Guolan (injection molding) has introduced more than 100 sets of high-end single-color or multi-color injection molding machines at home and abroad, reaching a monthly production capacity of 15 million pieces. It offer "one-stop service" of injection molding, spraying, printing and parts assembly.To provide customers with more efficient, stable and precise injection molding services,we get equipped with central feeding system, dust-free injection molding workshop, fully automatic injection molding auxiliary processing equipment, plastic parts and products laboratory.

Testing equipment

In order to guarantee high precision of mold parts size, we must make sure that ,during each procedure of the production, all of the parts can pass the test of hardness measuring instrument, depth gauge, two dimensional projector,and the three dimensional micrometer validation testing tools. At the same time we have mold laboratory and scientific test experience to ensure that our reliability and precision molds.